-

Phone:

+91 8220873979 -

Phone:

+91 9677497021 -

Working Hours:

Mon - Sat: 9:30 to 17:30

-

Phone:

+91 8220873979 -

Phone:

+91 9677497021 -

Working Hours:

Mon - Sat: 9:30 to 17:30

The Future of Machines

Discover cutting-edge machinery designed to enhance efficiency, productivity, and sustainability across diverse industries. We provide innovative solutions tailored to your specific needs.

Industrial Evolution

Explore our range of state-of-the-art machines, from precision robotics to intelligent automation systems. We empower businesses with the tools to thrive in the evolving manufacturing landscape.

Machinery Redefined

Experience the next generation of industrial technology. We deliver cutting-edge machinery that drives efficiency, innovation, and success.

Your Vision, Engineered to Perfection

Engineering Excellence

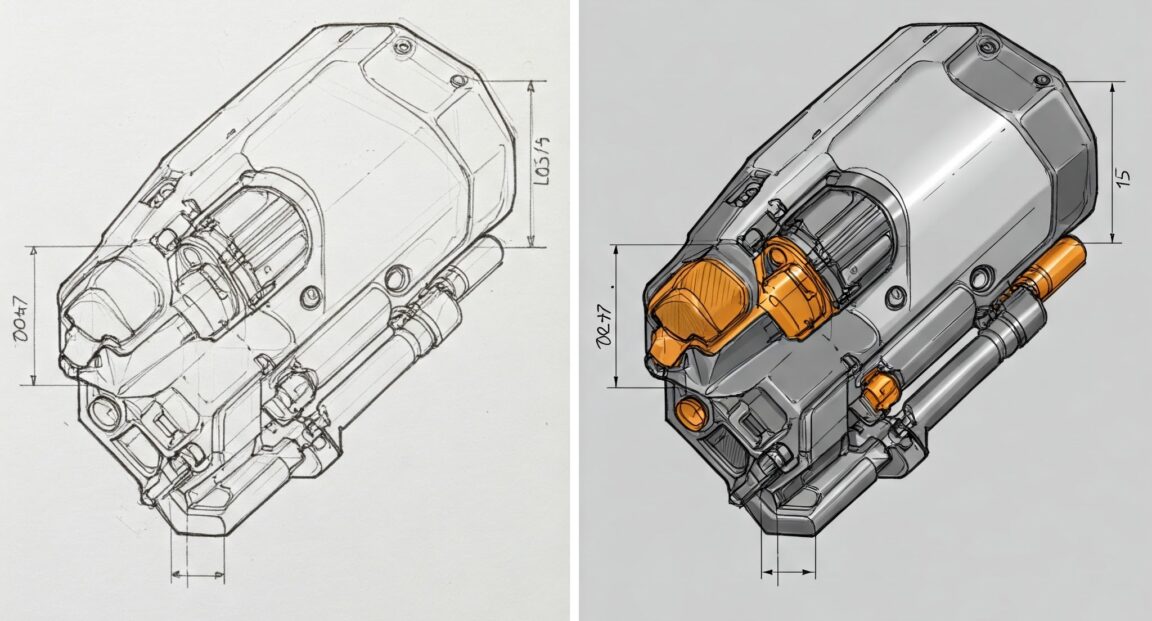

We provide comprehensive engineering services, from concept to production. Our team of experts leverages advanced tools like SolidWorks, CAE, and CFD to design, analyze, and optimize innovative machinery solutions.

Design for Innovation

We specialize in product design, development, and validation. Our focus is on creating high-performance machinery that meets your specific needs while optimizing for weight, cost, and performance.

Your Vision, Engineered

We translate your ideas into reality. Our services include CAD/CAM, CAE analysis, and technical documentation to bring your innovative machinery concepts to life.

10+

Years of expirience

Where Quality Meets Sustainability and Innovation

At Innovative Machineries, we’re not just in the business of industry; we’re in the business of transformation. With a legacy of innovatio.

45+

Experienced Professionals24/7

Transparent CommunicationTo deliver innovative, high-performance machinery and CAD/CAM solutions that empower businesses to achieve efficiency, precision, and excellence in their manufacturing processes. We aim to simplify complex challenges by designing and producing state-of-the-art solutions tailored to the unique needs of our clients.

To be a global leader in advanced machinery and CAD/CAM solutions, driving innovation and sustainability in the manufacturing industry, while setting new benchmarks for quality, reliability, and customer satisfaction.

Where Quality Meets Sustainability and Innovation

Engineering Analysis

Advanced simulations and analysis to optimize designs and ensure performance and reliability.

Technical Staffing

Provide skilled professionals tailored to your engineering and manufacturing needs.

Product Design

We create innovative, functional designs optimized for performance, cost, and durability.

SPM

Custom-built machines tailored to specific tasks, enhancing efficiency and precision.

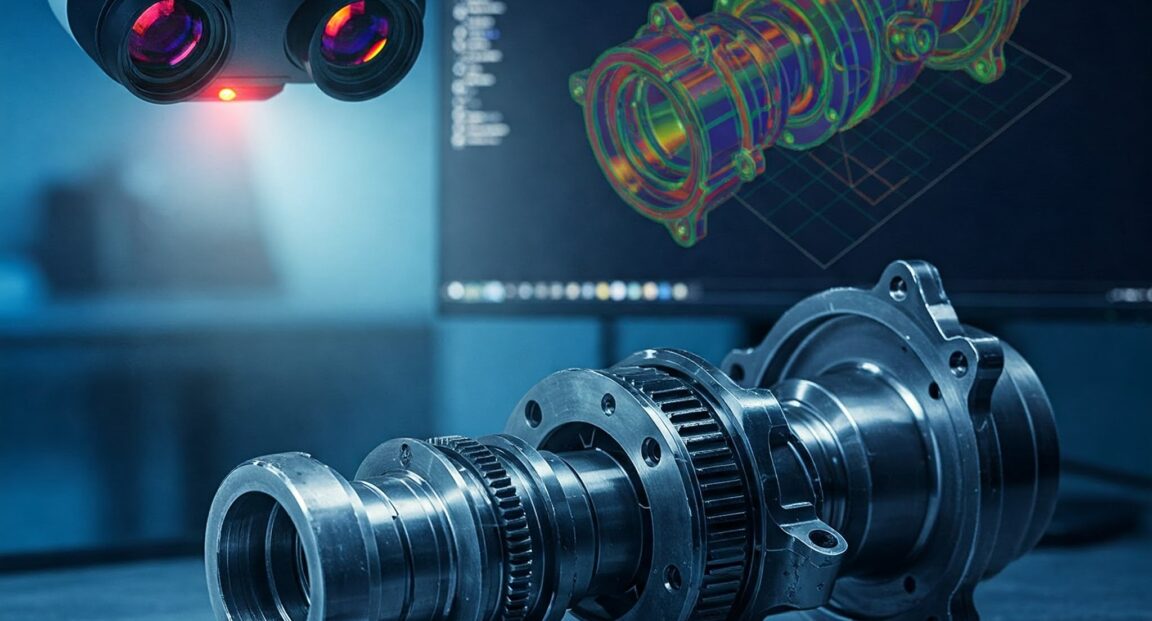

Reverse Engineering

Recreate, analyze, and improve existing components with high accuracy and precision.

Drawing Conversion

Convert hand-drawn or legacy designs into accurate, professional digital CAD files.

VTL (Vertical Turning Lathe)

VTL Overview: VTL (Vertical Turning Lathe) is a high-precision machining process designed for large and heavy workpieces. Unlike conventional lathes, VTLs have a vertically oriented spindle, allowing gravity to stabilize the workpiece for superior accuracy. This makes them ideal for machining large-diameter components like gears, flywheels, and turbine parts. How does a VTL differ from

HMC (Horizontal Machining Center)

HMC Overview: HMC (Horizontal Machining Center) is an advanced CNC milling system where the spindle is horizontally oriented. This setup allows for efficient material removal, better chip evacuation, and enhanced productivity, making it ideal for high-volume and complex part machining. How does HMC differ from VMC? HMCs have a horizontal spindle, enabling gravity-assisted chip removal

VMC Milling (3-Axis & 4th Axis)

VMC Milling Overview: VMC (Vertical Machining Center) milling is a precision machining process where a vertically oriented spindle removes material from a workpiece using rotary cutting tools. It is widely used for high-accuracy machining of complex components. What is the advantage of 4th Axis VMC over 3-Axis VMC? The 4th axis allows for rotation, enabling

CNC Turn Milling

CNC Turn Milling CNC Turn Milling Overview: CNC turn milling is a hybrid machining process that combines turning and milling operations in a single setup. It allows for the creation of complex parts with both cylindrical and prismatic features, improving efficiency and precision while reducing production time. How does CNC turn milling differ from CNC

CNC Turning

CNC Turning CNC Turning Overview: CNC (Computer Numerical Control) turning is a machining process where a cutting tool removes material from a rotating workpiece to create precise cylindrical parts. It is widely used in manufacturing for producing components with high accuracy, efficiency, and repeatability. What materials can be used in CNC turning? CNC turning works

Stories of Delight and Satisfaction

The product design services we received were outstanding. They helped us develop a highly efficient system that exceeded all our expectations. Professional and reliable every step of the way.

Arun Kumar

Operations Manager, TechSolutions Pvt. Ltd.We’ve worked with this team on multiple SPM projects, and their expertise has made a significant difference in our manufacturing processes. The custom machines they designed improved our productivity and reduced downtime.

Priya Nair

Lead Engineer, AutoMax IndustriesTheir reverse engineering service helped us recreate critical components with incredible accuracy. The team’s attention to detail and quick turnaround made all the difference in meeting our tight deadlines.

Vijayalakshmi Reddy

Head of R&D, InnovateTech Ltd.We’ve relied on their inspection services to ensure our products meet the highest standards. Their use of advanced tools and thorough approach gives us the confidence that our components are always top-notch.

Sundar Rajan

Quality Assurance Manager, Precision Parts Co.

1k

Project Completed

10+

Expert Team Member

50+

The Global Services

100%

Quality Assurance Rate

Unveiling Our Latest Triumphs and Transformative Endeavors

Building Construction

Developing eco-friendly packaging materials and implementing sustainable

Road Construction

Developing eco-friendly packaging materials and implementing sustainable

Industrial Construction

Developing eco-friendly packaging materials and implementing sustainable

Bridge Construction

Developing eco-friendly packaging materials and implementing sustainable

Request Your Personalized Quote Here

Our Latest Articles and Industry Updates

Vixa was founded in 1985 by a group of visionary engineers and metallurgists with a passion for excellence in construction

Build Your Career With Us: Opportunity Builds Here

At Vixa, we foster a dynamic and inclusive work environment that values innovation, collaboration, and personal growth.

Our employees are drawn to Vaxa because of our commitment to excellence, opportunities for career development, and supportive company culture.